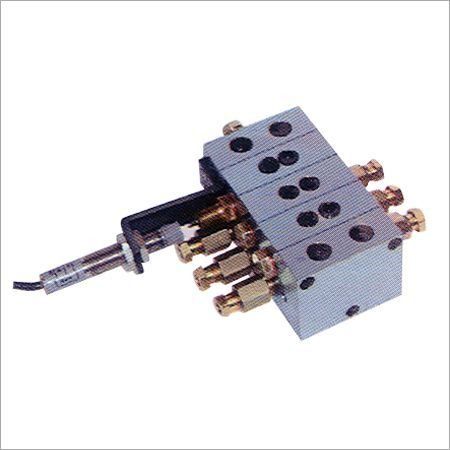

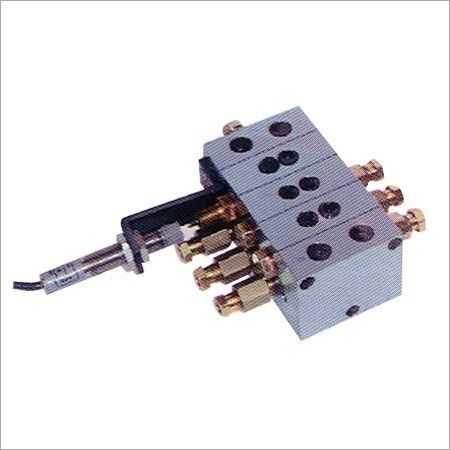

Dual Line Dose Feeder

Product Details:

Dual Line Dose Feeder Price And Quantity

- 1000 Piece

- 4000 INR/Piece

- 4000.00 - 20000.00 INR/Piece

Dual Line Dose Feeder Trade Information

- Cash on Delivery (COD) Cheque Cash Against Delivery (CAD) Cash in Advance (CID) Cash Advance (CA)

- 1000 Piece Per Month

- 1 Months

- All India

Product Description

Production DescriptionDose feeder is a block which has-two inputs to be connected with dual line coming from the lubrication pump. Depending upon the requirement there are different versions of dose feeders with varying no. of outlets. Dose Feeder is normally in vicinity of lubrication points, which are to be greased. Discharge quantity can be adjusted with grub screw provided in indicator assembly & functioning of each lubrication point can be seen by the movement of indicator.

Maximum working pressure 250 kg / cm. sq. Discharge/stroke/outlet=0.5cc to 1.5cc

| Model No. |

No. of Outlets |

LxHxW |

| CT-DLDF11 |

1 |

46x113x36 |

| CT-DLDF21 |

2 |

76x113x36 |

| CT-DLDF31 |

3 |

106x113x36 |

| CT-DLDF41 |

4 |

136x113x36 |

Maximum working pressure 250 kg / cm. sq. Discharge/stroke/outlet-1.5cc to 5cc

|

|

No. of Outlets |

LxHxW |

| CT-DLDF12 |

1 |

54x45x129 |

| CT-DLDF22 |

2 |

92x45x129 |

| CT-DLDF32 |

3 |

130x45x129 |

| CT-DLDF42 |

4 |

168x45x129 |

End Pressure Relay

- It consists of steel block having two ports where primary tube of dual line is tightened,

- There are also two pressure switches & 2 pressure gauge fitted on the block (one pressure switch & one pressure gauge for each line). We can set required pressure by adjusting screw, provided in pressure switch & visually we can check in pressure gauge.

- This senses the end pressure of lined & gives signal when pressure reaches the set valve

Piping and fittings are of high pressure & can withstand pressure upto 250kg/cm sq

Electric Control Panel:

The control panel has been provided for operation & control of the Dual Line Grease Lubrication System . The control Panel box is fabricated out of 2 mm thick, sheet & having over all dimensions as 600 x 400 x 175. All necessary contractors, timers, fuses, relays etc. are mounted on a removable plate, which is fitted inside the control panel box & can be taken out if required for any rectification / repair work. It can be mounted on any vertical surface. The controls / indications provided on the front panel are;

- L1-Main On Indication

- L2-Lubrication On Indication

- L3-Automode Indication

- L4-Manaul Mode Indication

- L5-Line 1 On Indication

- L6-Line 2 On Indication

- L7-Line 1 Fault Indication

- L8-Line 2 Fault Indication

- L9-Motor Trip Indication

- Pb1-Emergency Stop Button

- PB2- Start Button

- PB3